Introduction

|

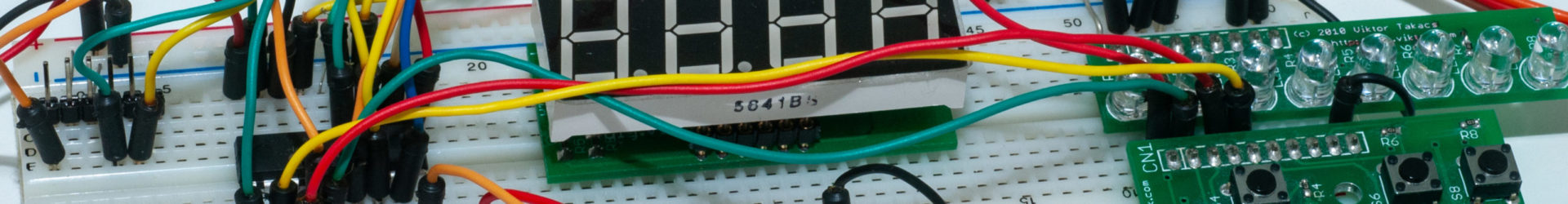

| The fully assembled unit – missing some decorative items after having been kicked around for the last 20 years… |

The circuit

|

| In the actual circuit I used the 74Lxx chips for low power consumption |

The circuit is operated from a 220V/24V transformer I had salvaged from some home appliance. Pretty much any transformer can be used for this purpose – although, if its output voltage is significantly different values of R1, R2, and R3 should be changed accordingly. In fact, a smaller one, around 6V would be ideal, as all the excess power is dissipated on the 7805. It’s not much because the whole circuit consumes very little current, but it wasn’t an ideal design. I used what I had at hand.

The time base for this circuit is taken from the mains supply, which is 50Hz. The required 2Hz and 1/60Hz (one pulse every 60 seconds) are obtained by feeding the 50Hz signal through a series of counters/dividers.

As a point of interest, until 1986 the 50Hz of the mains supply was very unreliable in Hungary – clocks based on this were never punctual; they easily gained or lost up to 10 minutes per day. After the Chernobyl disaster, though, Something must have changed, because from then on the 50Hz was indeed 50Hz – well, within reason, but that was already good enough to base a clock on it.

The 1/60Hz signal is used to increment the time counter every minute, while the 2Hz signal is used to fast forward the settings using S1, S2, and S3.

In the default states of S4 and S5, the alarm is ON only when all time decoder ICs (IC9, IC10, IC11) have their last displayable LED lit up – in other words, the connected device is only on for one minute.

If S5 is in the [1-2] position, it will still allow the timer to switch on the connected device, but it will continue to be on even after a minute, thanks to the flip-flop created by logic gates IC12A and IC12B. To switch off the connected device S5 needs to be set back to its default position [3-2].

Switching S4 to the other position [2-1] allows the connected device to be switched on any time, overriding any alarm settings.

Finally, below is the original schematics.

|

| At the time I didn’t have a computer, let alone a schematics designer… |

Printed Circuit Board

|

| Solder side: The reason why the PCB became so oblong is that I had a very long (~1m * 6cm) stripe of double sided PCB. |

The circuit is built on a piece of double sided PCB. This was my first double sided PCB made at home using photo transfer technique. It didn’t work very well at the first time, so on the PCB I had to fix many traces. In subsequent projects I had very good results, though.

The PCB design of the component side has been lost over the years (which is strange, since I keep all the materials in the same place…). 🙁

Mechanical build-up

|

| At the top and ant the bottom, where some ugliness can be seen now horizontal stripes of coloured ribbon cables used to be to enhance geekiness… |

After the circuit was put together and was working as expected, I added two extra LEDs: a red one at the top to blink at 0.5Hz (otherwise the whole thing looked very static), and a yellow one below the switches that was a visual indication of the switched device.

|

| All the extra wires were needed to fix problems during the making of the PCB. They were not caused by faulty design. |